Assembly, as one of the stages of the production process, brings significant challenges in terms of efficiency, quality and cost-effectiveness of production. Assembly work performed in a traditional way is time-consuming, tedious, repetitive, and sometimes may involve some risk and harm to employees. An inherent part of manual assembly processes is increased susceptibility to errors caused by monotonous work mode, which also translates into difficulties with employee turnover. Therefore, manual assembly processes are increasingly being replaced by more effective semi-automatic or even fully automated systems.

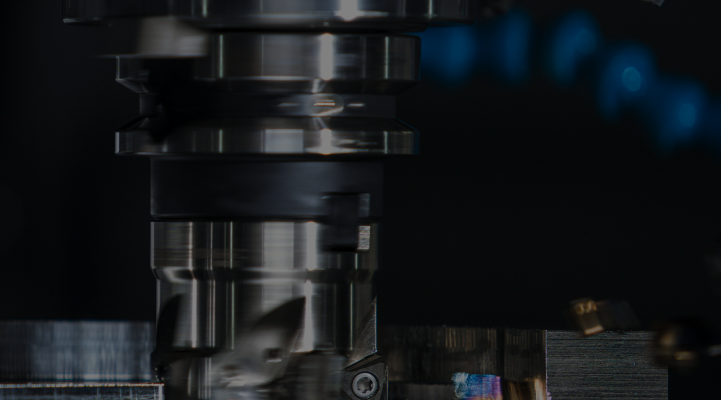

At TKM Projekt, we construct advanced robotic assembly stations that allow companies to reduce costs, shorten production time and manage their staff more effectively.