Application

Ensuring adequate packaging efficiency to the processing capacity of the production line and increasing precision in the palletizing process is a challenge facing every production company. Companies in this sector must also strive for greater flexibility. Taking into account the market tendency towards increasingly shorter product life cycles, modern production lines must allow for the reorganization of production and its easy adaptation to new conditions.

Staff shortages are also an important factor affecting the plant’s production capacity. Work in palletizing and packaging is hard and monotonous, which causes problems with frequent employee absences due to sick leave, high employee turnover and difficulties in recruiting new people. Therefore, many companies recognize the need to free employees from heavy tasks that may be dangerous and injurious to them. Then, robotic stations for palletizing and packaging turn out to be a profitable solution.

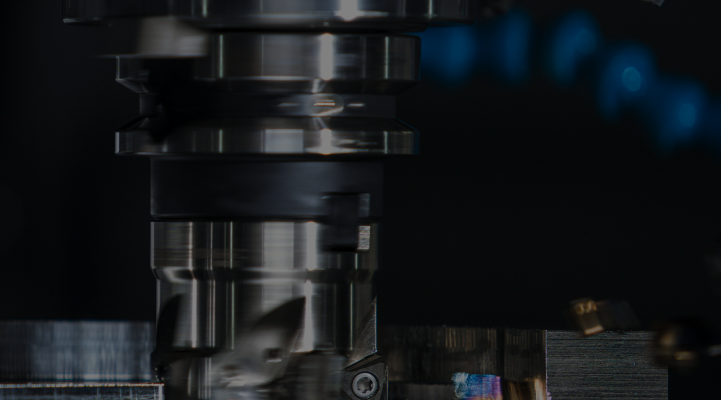

Virtually every industry requires packaging and palletizing the final product. The food, cosmetics, metal, chemical and pharmaceutical industries – each of them needs solutions that will enable the packaging of as many products as possible in the shortest possible time while maintaining high quality and eliminating the risk of damage.