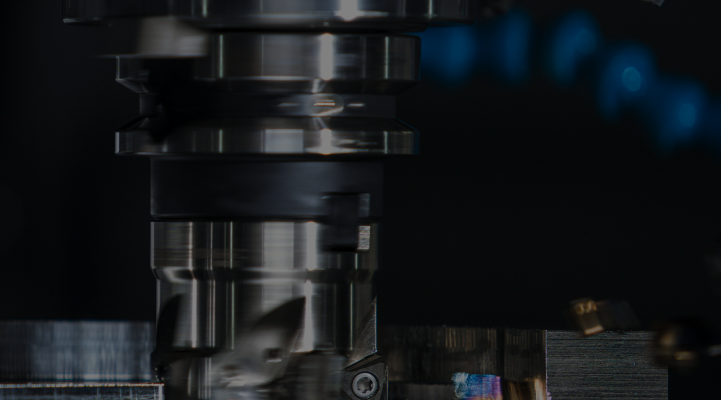

Assembly stations are a key element of the production process, during which specific functional and operational characteristics of the product are provided. Thanks to automation, they enable the assembly of final products faster, more effectively and in compliance with all quality and safety standards.