Rising labor costs are one of the key factors that make various manufacturing companies gradually move away from manual control of processes and increasingly focus on their automation. This applies especially to inspections of large-scale production, where proper compliance with strict control requirements is difficult, and sometimes even impossible, without implementing an automated system.

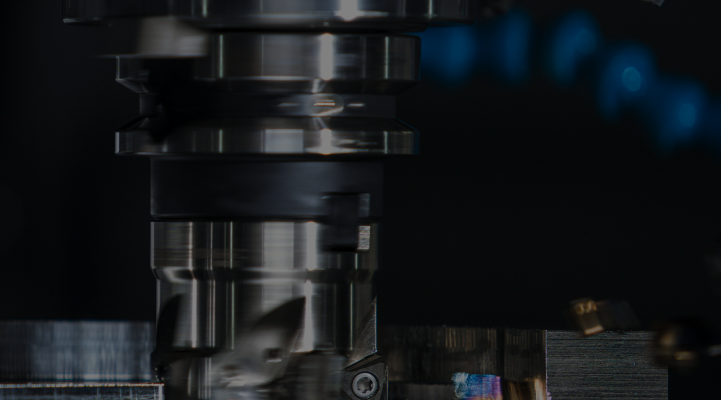

Visual inspection for surface defects is the basis for correctly assessing the quality of the manufactured element at every stage of the production process. This allows you to quickly detect defects, reduce production losses, and thus provide customers with high-quality final products. At TKM Projekt, we design advanced solutions in this area in accordance with the device standard applicable in a given company.